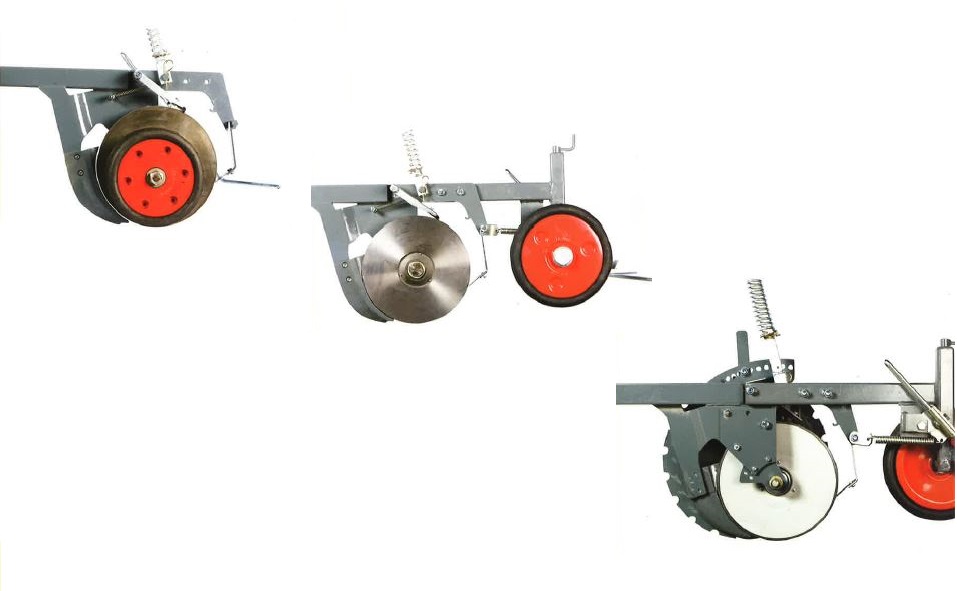

Herriau seed drills

Superior crop establishment

Possibly in combination with other seedbed preparation equipment, Herriau seed drills ensure accurate seed placement, planting seeds at a uniform depth with the right spacing. Our seed drills are ISOBUS-ready and can be connected directly to your tractor’s display screen.